Hot Dip Galvanising

Galvanizing is a process that provides a protective coating to iron and steel to prevent corrosion. When iron is extracted from its ore and converted into usable form, it becomes vulnerable to the natural elements and begins to corrode. Galvanizing serves as a powerful solution to this issue by creating a protective barrier on the surface of iron and steel. This coating acts as a shield, preventing the metal from reacting with the environment and slowing down the process of corrosion. By undergoing galvanizing, iron and steel can be economically utilized for various applications while maintaining their integrity and longevity.

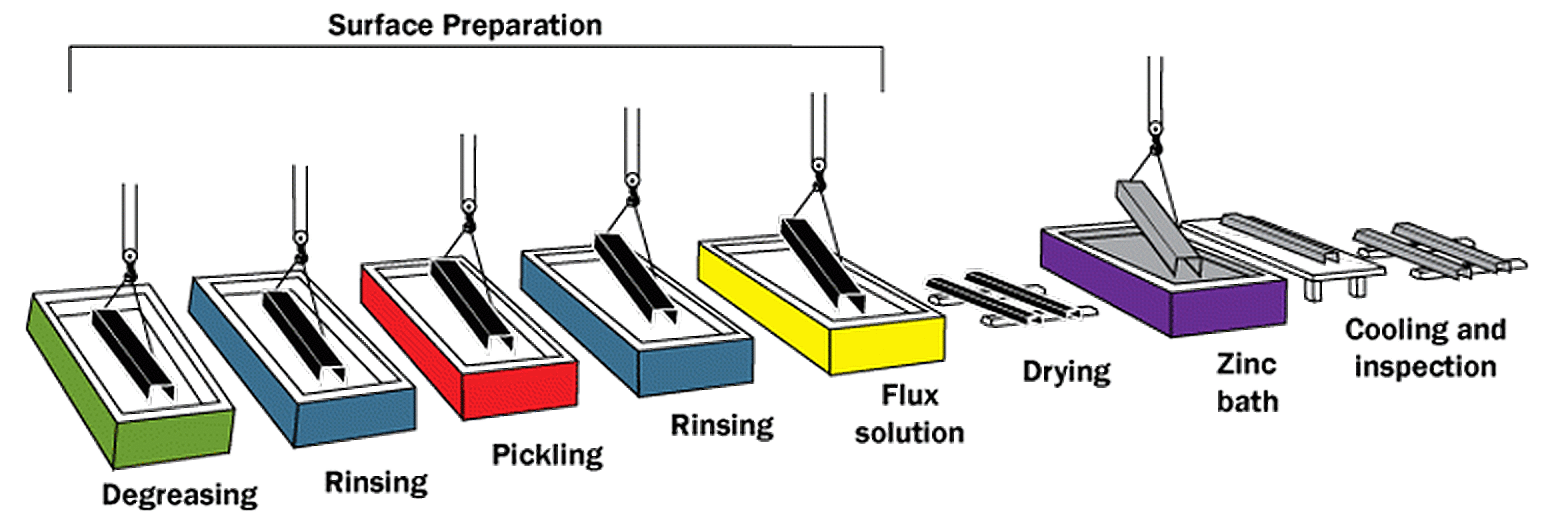

Hot Dip Galvanizing Process Flow

In adherence to the guidelines set by the Maharashtra Pollution Control Board (MPCB), our galvanizing and acid bath facilities are equipped with a Fugitive Emission suction system connected to a scrubber system. This system utilizes a water jet to capture and contain any potential emissions, which are then safely discharged through a chimney. Our commitment extends beyond creating a worker-friendly environment to also include maintaining pollution-free surroundings in accordance with regulatory standards.

Advantages of

Hot Dip Galvanising

- Competitive First Cost

As a highly mechanized, closely controlled process, Hot Dip Galvanizing can be carried out economically in large batches. The alternative – painting – is highly labor intensive.

- Lowest Lifetime Cost

Low initial cost and long life make Hot Dip Galvanizing the most versatile and economical way of protecting steel for extended periods (25 + years).

- Long Life

Hot Dip Galvanizing has many years of proven performance. Long life of up to seventy years is commonplace in most atmospheres, for more details see the Millennium Map Project.

- Reliability

The process is simple, straightforward, and closely controlled. The coating thicknesses are regular, predictable, and easily specified and are defined by I.S. EN IS 1461: 2009.

- Speed of Application

A fully galvanized protective coating can be applied in a few hours. A proper four-coat paint system requires approximately one week.

- Complete Coverage

Because it is dipped in molten zinc, all parts of the surfaces are coated – inside and out – including awkward corners and narrow gaps.

- Coating Toughness

Hot Dip Galvanizing is unique – the coating bonds metallurgically with the steel giving a much greater resistance to damage than other coatings.

- Three-Way Protection

- It weathers at a slow rate giving a long and predictable life.

- The coating sacrifices itself to any small areas exposed through drilling, cutting, or accidental damage.

- If large areas get damaged it prevents the sideways creep of rust.

- Ease of Inspection

Hot Dip Galvanizing is an honest coating – if it looks continuous and sound, it is so. Coating thickness can be checked easily with the use of a magnetic probe (Elcometer).

- Faster Construction

Hot Dip Galvanized steel is ready for use. No further site preparation, painting, or inspection is necessary. Once erected, cladding can begin immediately, thus accelerating the construction program.

Plant Specifications

| Sr. No | Description | Quantity (Nos.) | Sizes in meters | ||

|---|---|---|---|---|---|

| Length | Width | Height | |||

| 1 | Degreasing Tank | 1 | 5 | 1.2 | 1.8 |

| 2 | Rinsing Tank 1 | 1 | 5 | 1.2 | 1.8 |

| 3 | |||||

| 4 | Pickling Tanks | 3 | 5 | 1.2 | 1.8 |

| 5 | Rinsing Tank 2 | 1 | 5 | 1.2 | 1.8 |

| 6 | Pre-Flux Tank | 1 | 5 | 1.2 | 1.8 |

| 7 | Dryer Pit | 3 | 5 | 2.5 | 2.0 |

| 8 | Zinc Kettle | 1 | 5 | 1.2 | 1.8 |

| 9 | Furnace Type | 1 | High-Velocity Pulse Fired Fully automatic furnace with LPG as Fuel. | ||

Post Treatment Facilities

| Sr. No | Description | Quantity (Nos.) | Sizes in meters | ||

|---|---|---|---|---|---|

| Length | Width | Height | |||

| 1 | Quenching Tank | 1 | 6 | 1.2 | 1.8 |

| 2 | Passivation Tank | 1 | 6 | 1.2 | 1.8 |

| 3 | Galvanizing Capacity | 2500 MT/ Month | |||

Material Handling Facilities

| Sr. No | Location | Description | Quantity (Nos.) |

|---|---|---|---|

| 1 | Shop Floor Area | EOT cranes of 5 Tonnes Capacity with Two Hoists (4 Tonnes Capacity) Mounted on it. | 2 Nos. |

| 2 | Loading / Unloading & Storage Area | EOT cranes of 5 Tonnes Capacity with Two Hoists (2 Tonnes Capacity) Mounted on it. | 1 Nos. |

| D.G. SET | 1 No. 125 KVA Capacity | ||

| Power | 200 HP MSEB | ||

Effluent Treatment Plant

| Sr. No | Description | Quantity |

|---|---|---|

| 1 | Collection Tank | 1 No. |

| 2 | Reaction Tank with caustic & Lime addition by air agitation | 2 No. |

| 3 | Settling Tank | 1 No. |

| 4 | Sand Bed for collecting Solid wastes (Lime Sludge) | 2 No. |

Testing Facilities at Airseal

-

Thickness Gauge

To Measure Zinc coating at any point in microns

-

Preece Test

Copper Sulphate solution test for uniformity of zinc coating

-

Stripping Test

Mass of Zinc coating in Grams/m2 with electronic weight scale.

-

Hammer test & Knife Test

Adhesion of zinc coating with standard hammer & knife

-

Chemical Balance

Digital 0-3 Kg Contech make.

-

Weighing Platform Scale

0-1 Tonne capacity Contech Make.

-

Facilities for Testing (Internal Parameters)

Acid Strength with hydrometer burette & pipette Iron Content in pickling & pre-flux tank etc.

Other Products

Airseal

Airseal is a revolutionary airtight solution designed to address the challenges of ash leakage and air ingress in....

Aeropower

Aero Power, a division of AirSeal Technology LLP, specializes in providing customized solutions....

Grating

Airseal Technology LLP is a leading player in the thermal power plant industry, offering a wide range of....