Grating

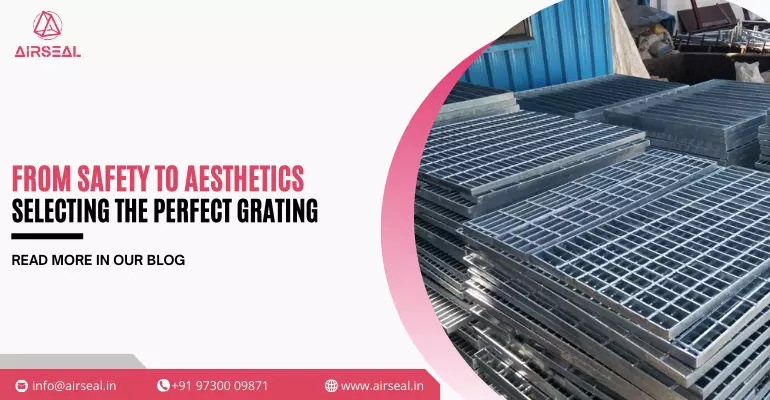

Airseal Technology LLP is a leading player in the thermal power plant industry, offering a wide range of high-quality gratings for various applications. With state-of-the-art facilities, we are capable of producing over 50 metric tons of grating panels per day, utilizing both manual and automatic machinery. Our efficient manufacturing process allows us to meet our client's urgent needs and deliver ready-to-dispatch grating panels on short notice.

Our gratings are available in standard sizes and meshes, catering to the diverse needs of clients worldwide. We offer a variety of grating types including electro-forged gratings, manual punching gratings, serrated gratings, and plain gratings. Our gratings are made from mild steel and can be supplied in self-color, hot-dip galvanized, or painted surface finish

In addition to standard gratings, we also offer custom-fabricated electro-forged gratings, circular gratings, heavy-duty gully gratings, and stair treads, complete with the necessary fixing clamps. Our gratings come with both plain and serrated bearing bars, ensuring maximum safety and durability Airseal Technology LLP is committed to providing our clients with the highest quality gratings, backed by our extensive industry experience and expertise. Our dedication to customer satisfaction and commitment to using the latest technology has established us as a trusted and reliable supplier in the thermal power plant industry.

Applications of

Gratings

- Electro Forged Gratings

Electro-forged gratings are widely used in industrial settings such as oil and gas refineries, power plants, and chemical processing facilities because of their high strength and durability. They are suitable for heavy-duty applications such as platforms, walkways, stair treads, and mezzanine flooring. The high-temperature forging process creates a tight and compact structure, which makes the gratings resistant to impact and corrosion. They can also withstand heavy loads and traffic, making them suitable for areas where vehicles and heavy machinery are in use.

-

Manual punching gratings

Manual punching gratings are typically less expensive than electro-forged gratings and are suitable for less demanding applications. They are often used in walkways, stair treads, and mezzanine flooring in commercial and industrial buildings. They are also suitable for use in pedestrian bridges, decks, and ramps. Although they have a lower load-bearing capacity compared to electro-forged gratings, they can still support moderate loads and traffic.

-

Serrated gratings

Serrated gratings are specifically designed to provide additional slip resistance, which makes them suitable for outdoor applications such as bridges, decks, ramps, and walkways. They are also suitable for use in industrial settings where workers are at risk of slipping, such as on wet or oily surfaces. The serrations on the surface of the grating provide an increased level of traction, which reduces the risk of accidents and injuries.

-

Plain gratings

Plain gratings are smooth and have no serrations or teeth on the surface. These gratings are often used in indoor applications such as in buildings, and in areas where a smooth surface is desired. They are suitable for use in areas such as stair treads, mezzanine flooring, and walkways. They are also suitable for use in areas where heavy machinery and vehicles are not in use. The smooth surface of plain gratings is easy to clean and maintain, and it does not trap dirt or debris.

Manufacturing of Industrial Gratings

Our gratings are made from mild steel which is a type of low-carbon steel that is easy to work with and has good weldability and formability properties. Mild steel is also known for its corrosion resistance, making it a suitable material for gratings that will be used in outdoor environments.

Our gratings can be supplied in a self-color finish, which means that they have not been treated or coated with any additional materials. This finish is suitable for indoor applications where the gratings will be protected from the elements.

We also offer a hot-dip galvanized finish for our gratings. This finish involves immersing the gratings in molten zinc, which forms a protective zinc coating on the surface. This coating provides an additional layer of protection against corrosion, making the gratings suitable for use in outdoor environments. Hot-dip galvanized finish is a cost-effective and durable option for gratings that will be used in industrial or heavy-duty applications.

Lastly, we can provide a painted surface finish on our gratings. This finish involves applying a layer of paint to the surface of the gratings, which can improve their appearance and provide additional protection against corrosion. Painted gratings are suitable for use in indoor or outdoor environments, and they can be customized to match the color scheme of the project.

Use of Gratings in the Thermal Industry

Other Products

Airseal

Airseal is a revolutionary airtight solution designed to address the challenges of ash leakage and air ingress in....

Aeropower

Aero Power, a division of AirSeal Technology LLP, specializes in providing customized solutions....

Hot Dip Galvanising

Galvanizing is a process that provides a protective coating to iron and steel to prevent corrosion....